OHSU Health & Healing Center

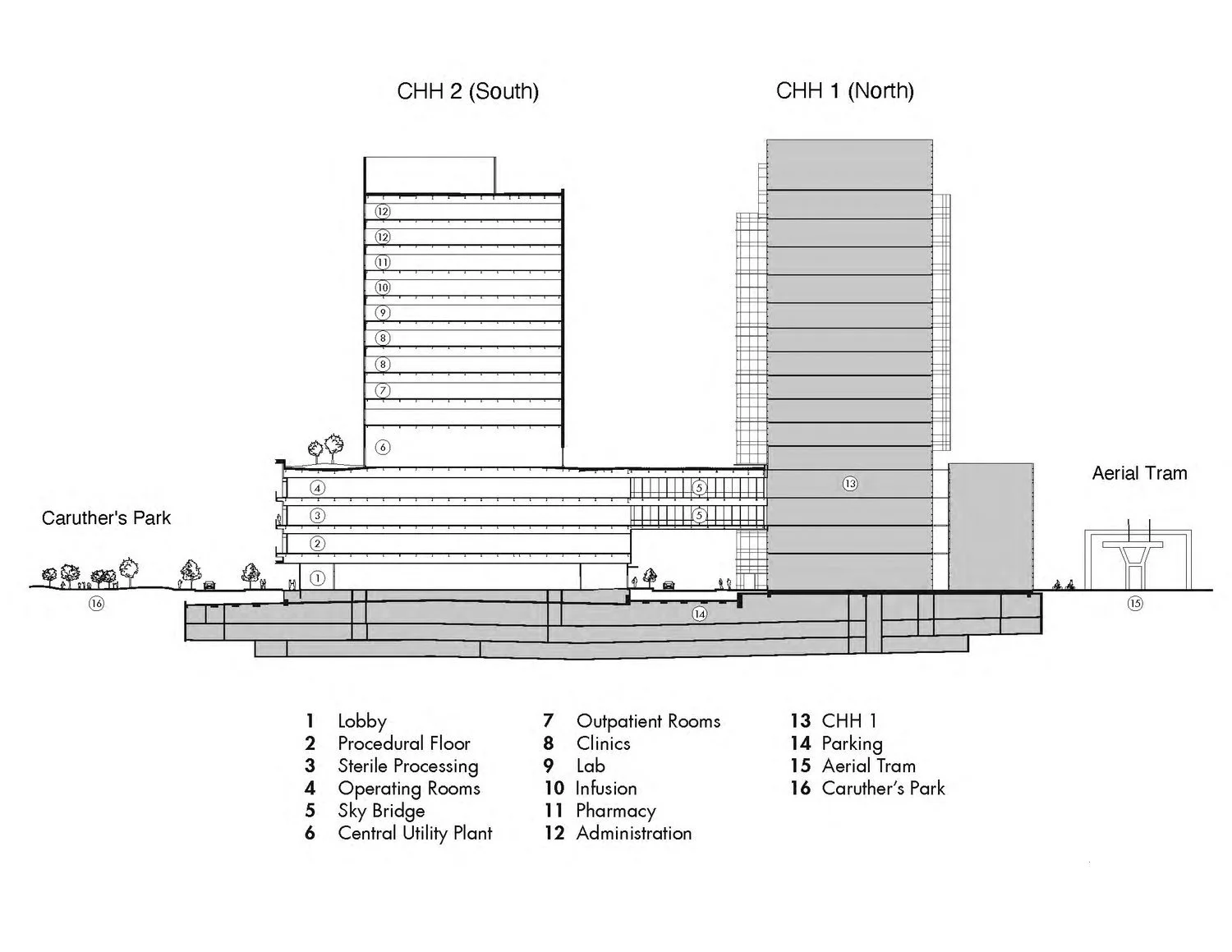

A 15-story ambulatory health center constructed on a tight footprint demonstrates Open Building flexibility by separating “hard” structural/service zones from “soft” spaces to accommodate diverse user-driven programming within a resilient, high-performance facility.

Center for Health & Healing Building 2 (2019)

Portland, Oregon, USA

The Challenge

Oregon Health & Science University needed to expand its clinical and research capacity by constructing—over an existing garage—a single expansive structure that would accommodate its wide range of medical services and anticipate its future needs.

Key Issues

Fixed structural limits were dictated by tight zoning and the need to be built above an existing garage.

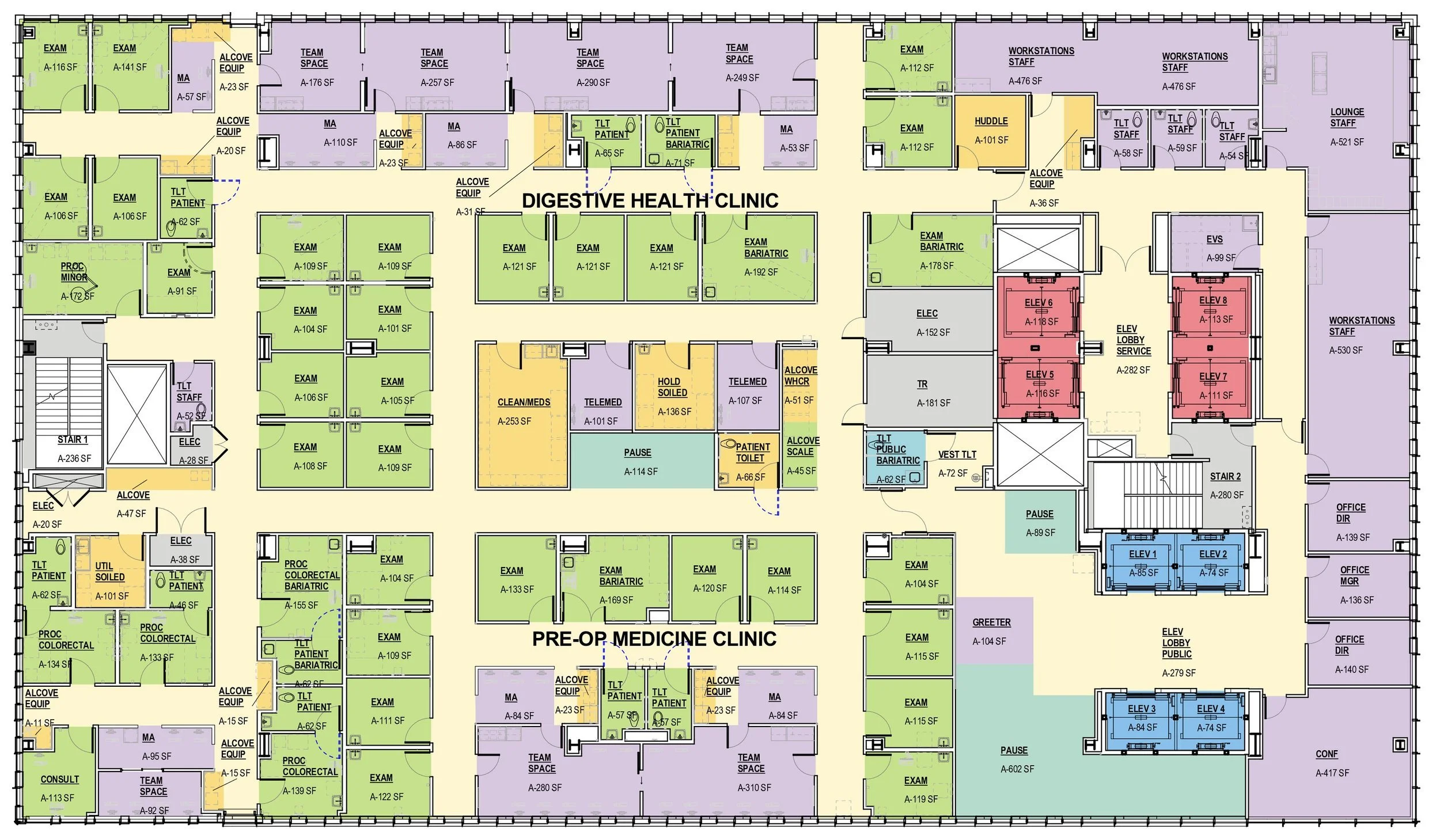

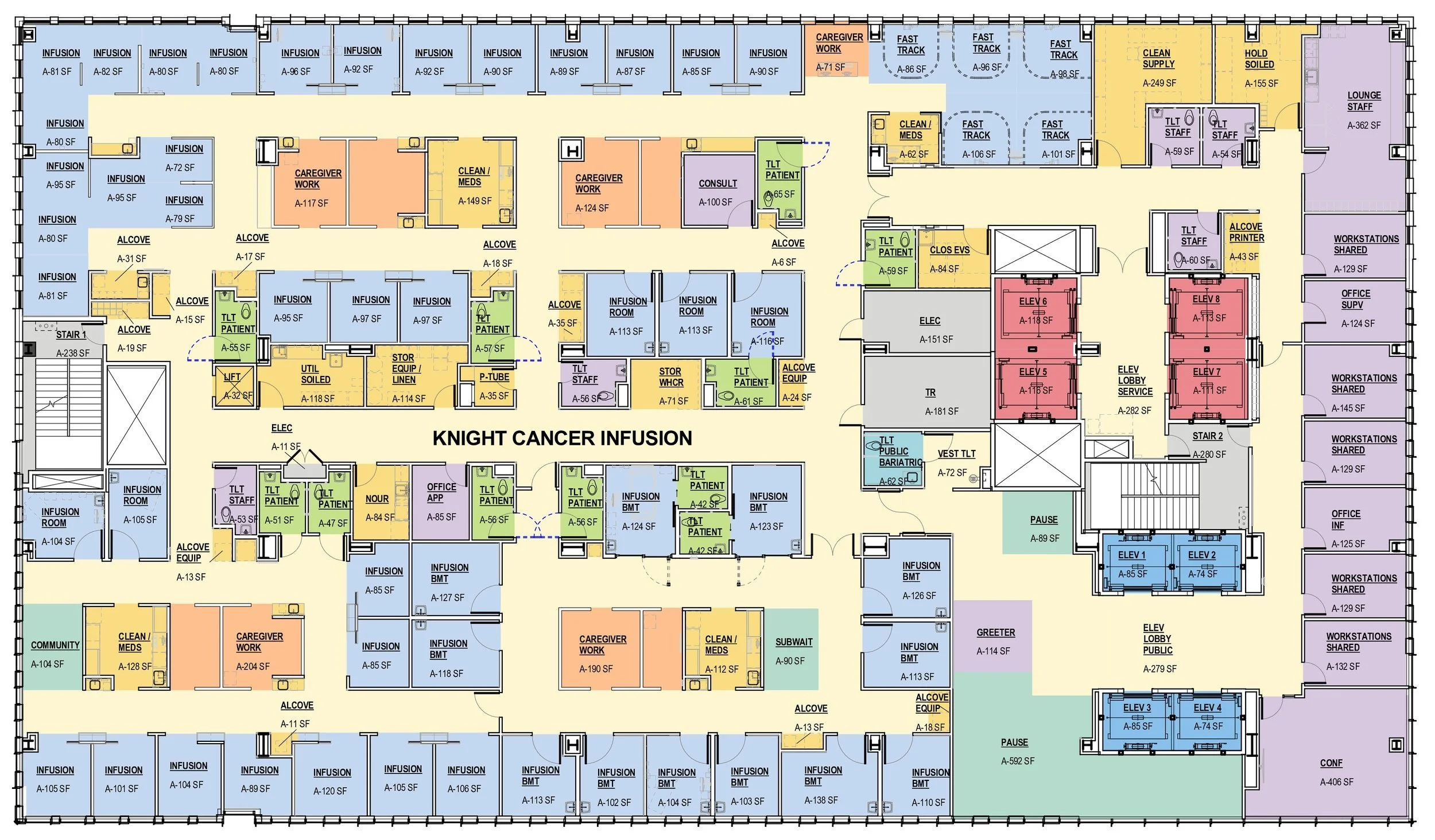

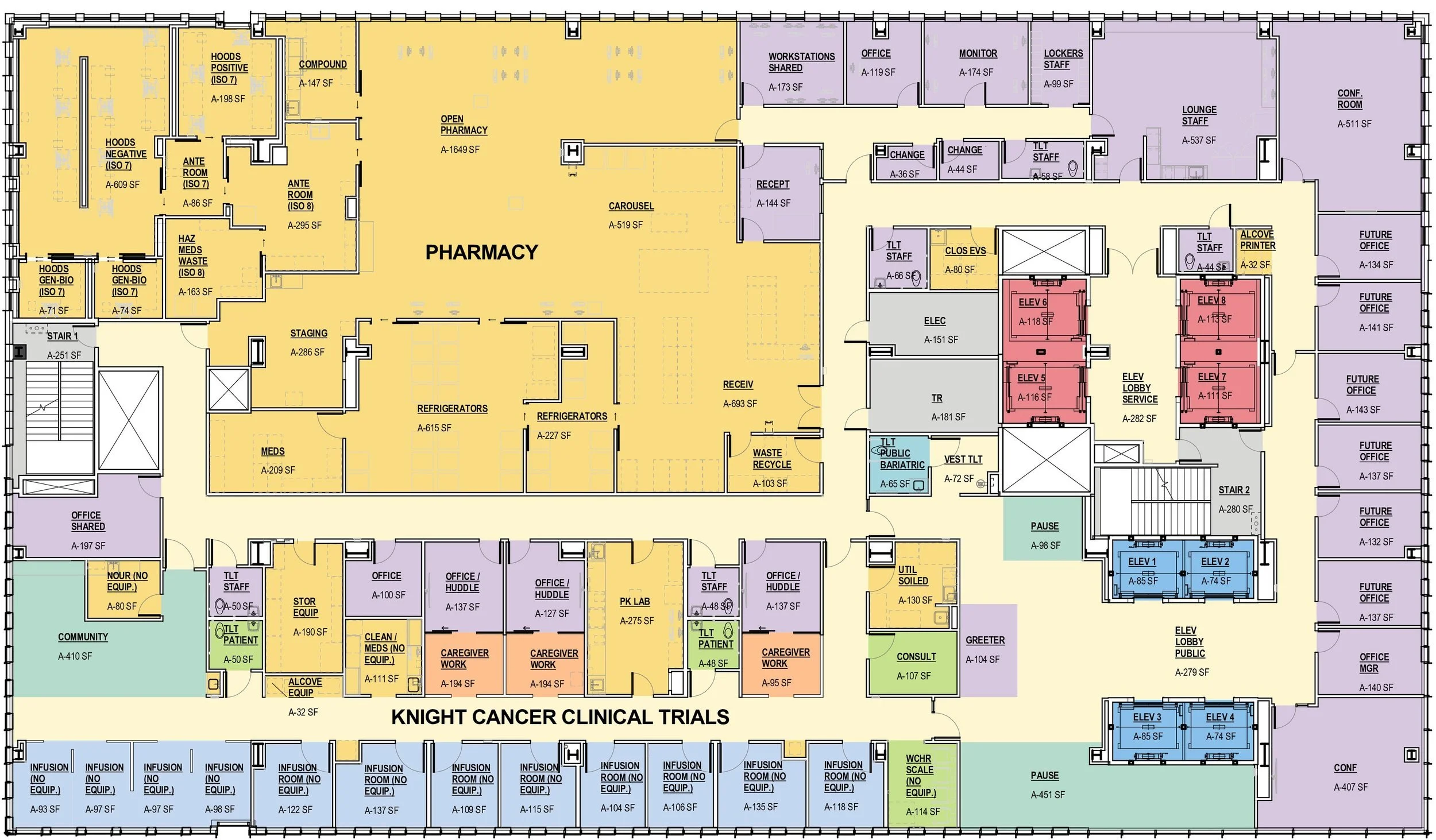

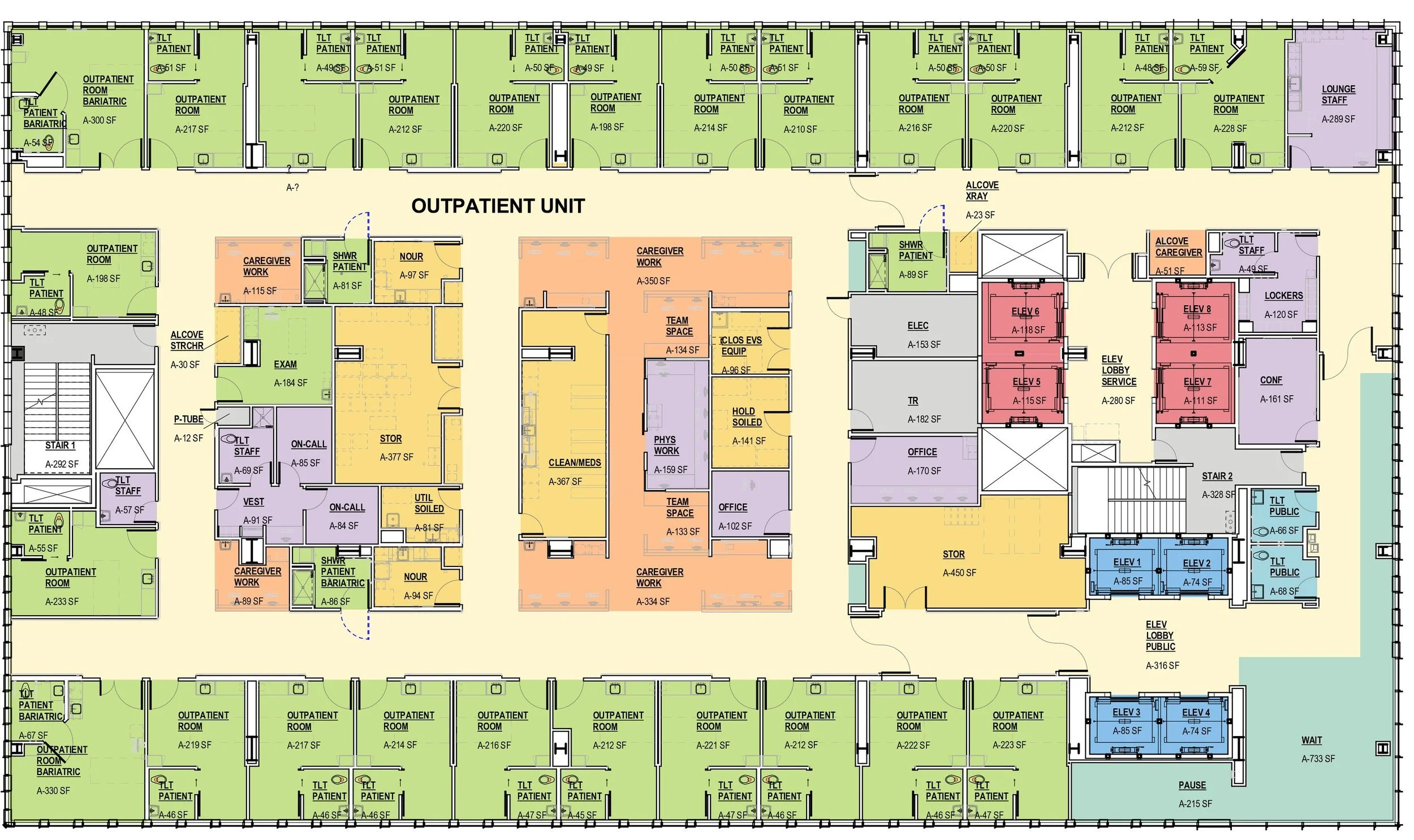

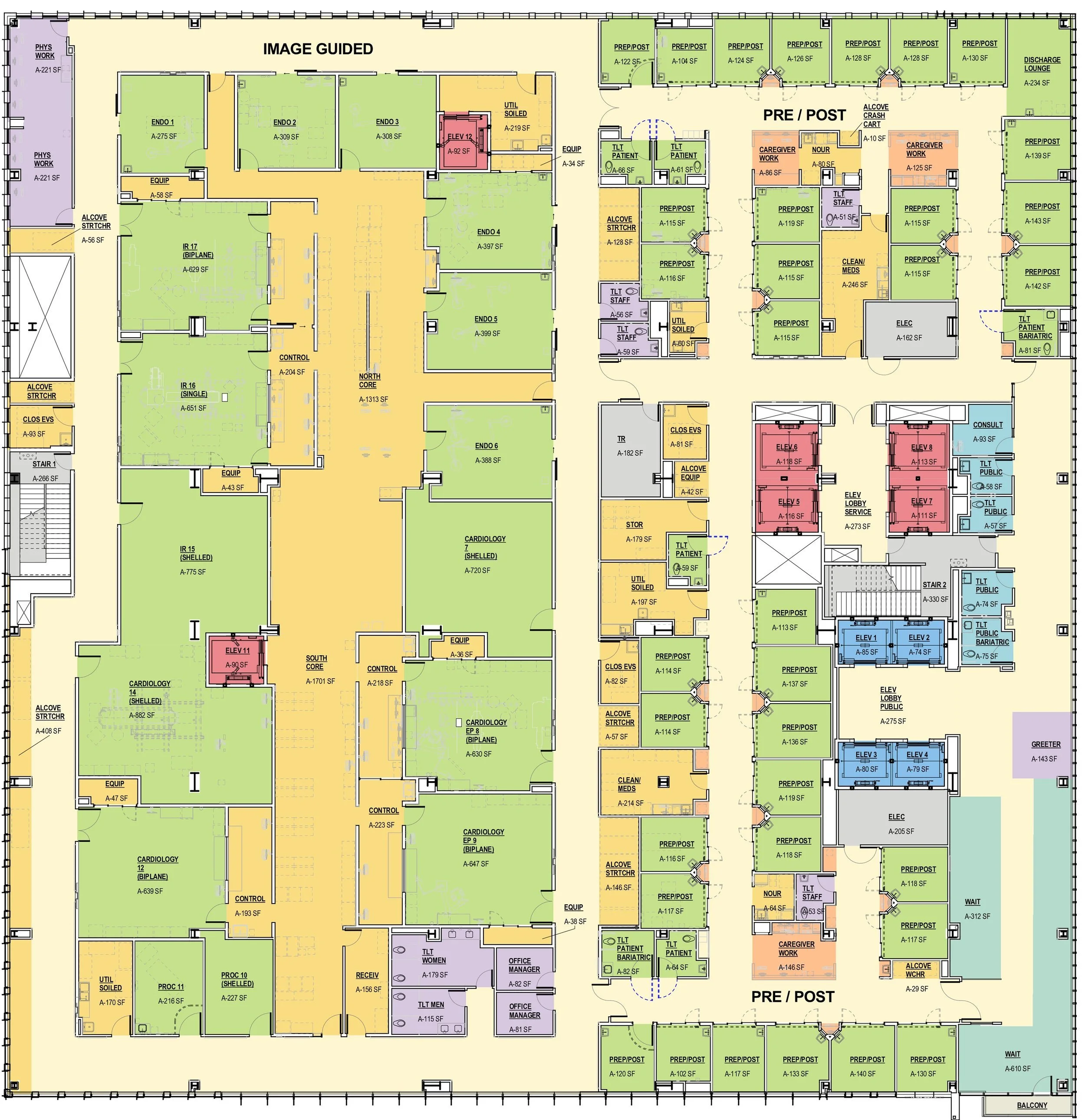

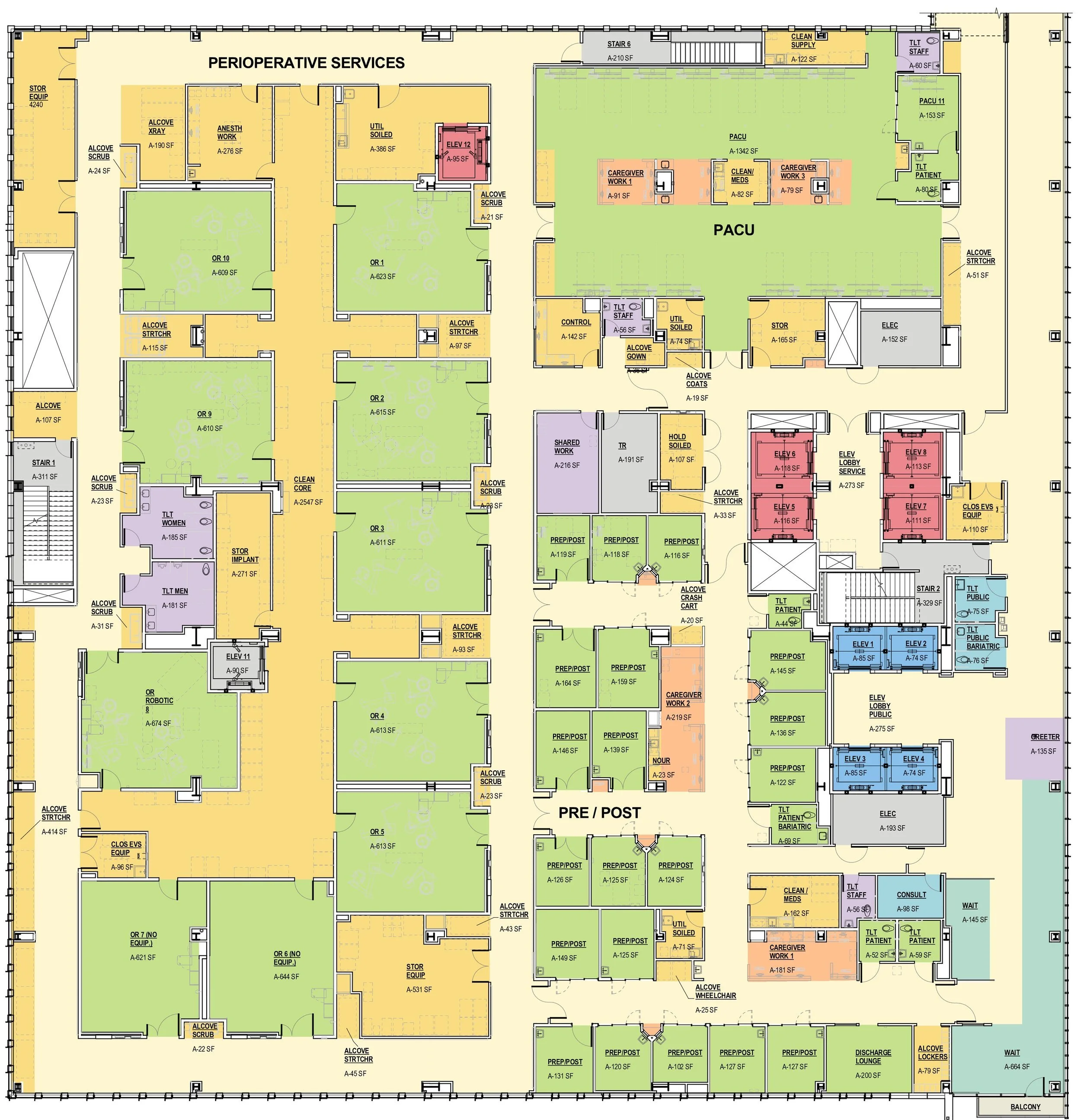

Wide-ranging clinical programs required vastly different spatial and mechanical needs.

Future-proofing requirements demanded extra capacity and modular planning.

Involvement of end-users in design introduced workflow complexity.

The Ambitions

To build a high-performance ambulatory care and research facility that could evolve with changing needs, the design—which utilized input from stakeholders at every level of operations—emphasized a clear separation of the permanent structure from short-term infill.

Strategic Goals

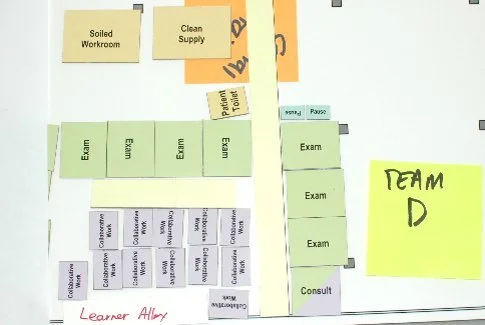

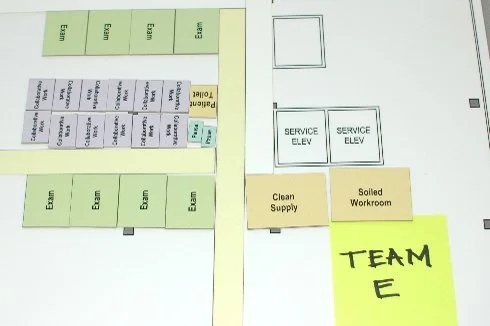

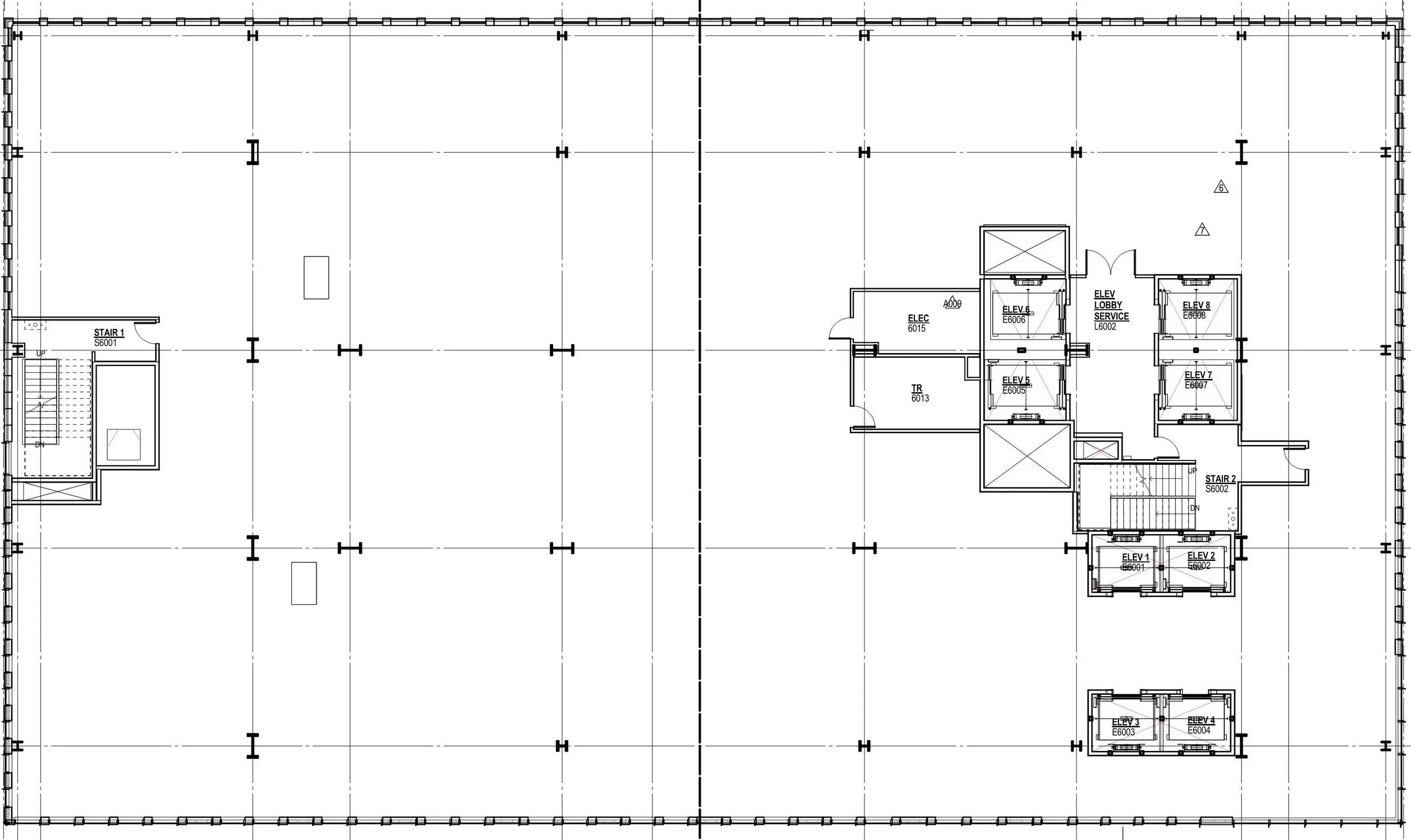

Create a universal floorplate with standardized planning modules and column-free zones.

Cluster structural and mechanical, electrical, and plumbing cores to preserve flexible, reconfigurable clinical zones.

Include spare capacity in infrastructure to support future expansion.

Embrace a lean design that eliminates inefficiencies, guiding everything from layout of clinics to just-in-time construction logistics

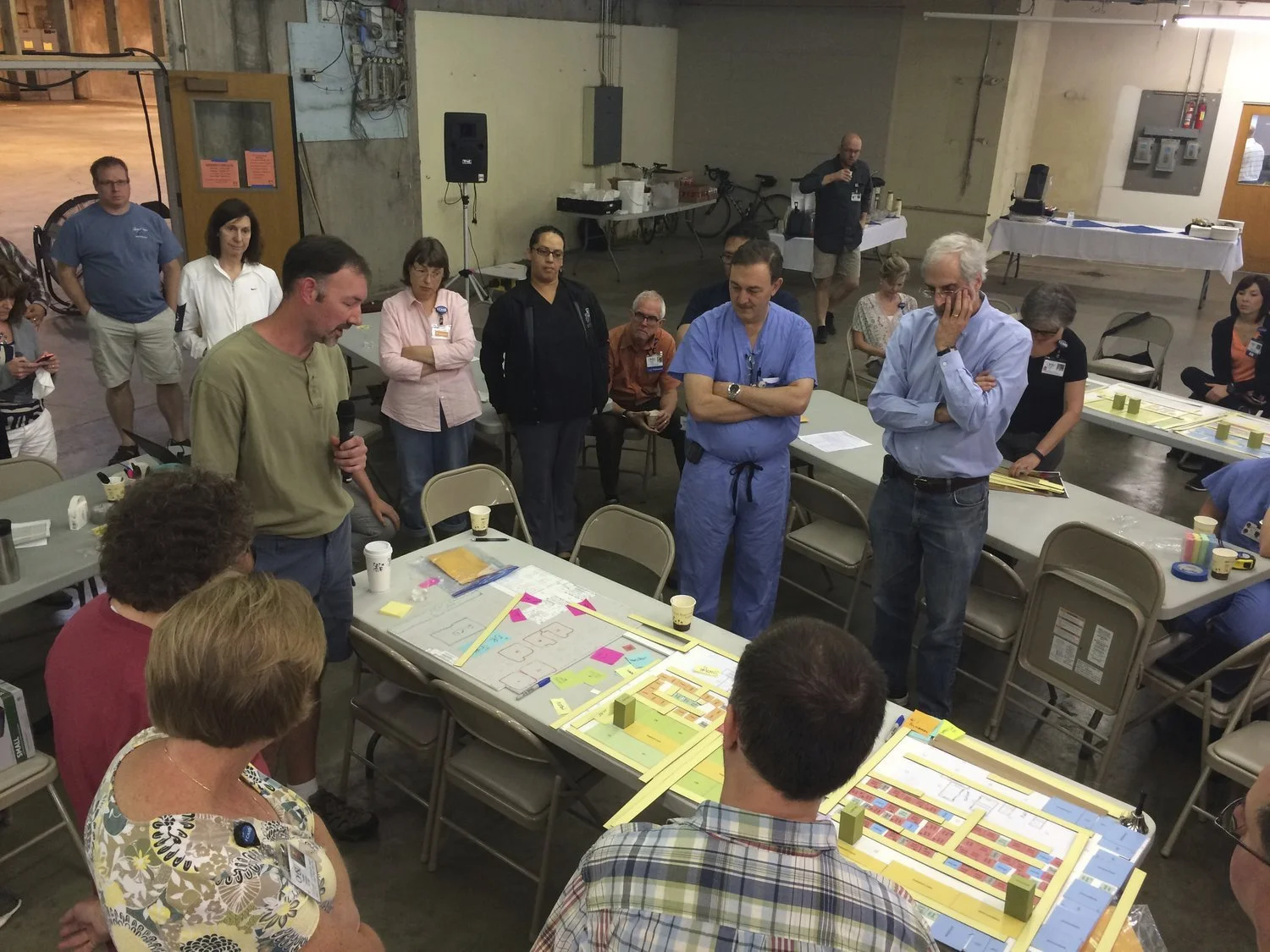

Leverage a fully integrated team approach where architects (ZGF), engineers, contractors, and end-users co-created the design.

The Realization

Delivered through integrated project delivery, CHH-South was completed on time and on budget. Key systems—including HVAC, structure, and utilities—were planned for longevity and change. Interior spaces were mock-tested and built for modular adjustment.

Vital Design Choices

The central spine of fixed structural and service elements provide consistent and predictable “hard” zones.

A universal five-foot grid—extending to the facade—enables easily reconfigurable “soft” zones without service disruption.

All major building systems were built with 20–25% spare capacity to support future expansion.

Collaborative planning and construction with the core team all located in a single large room for the duration of design and construction.

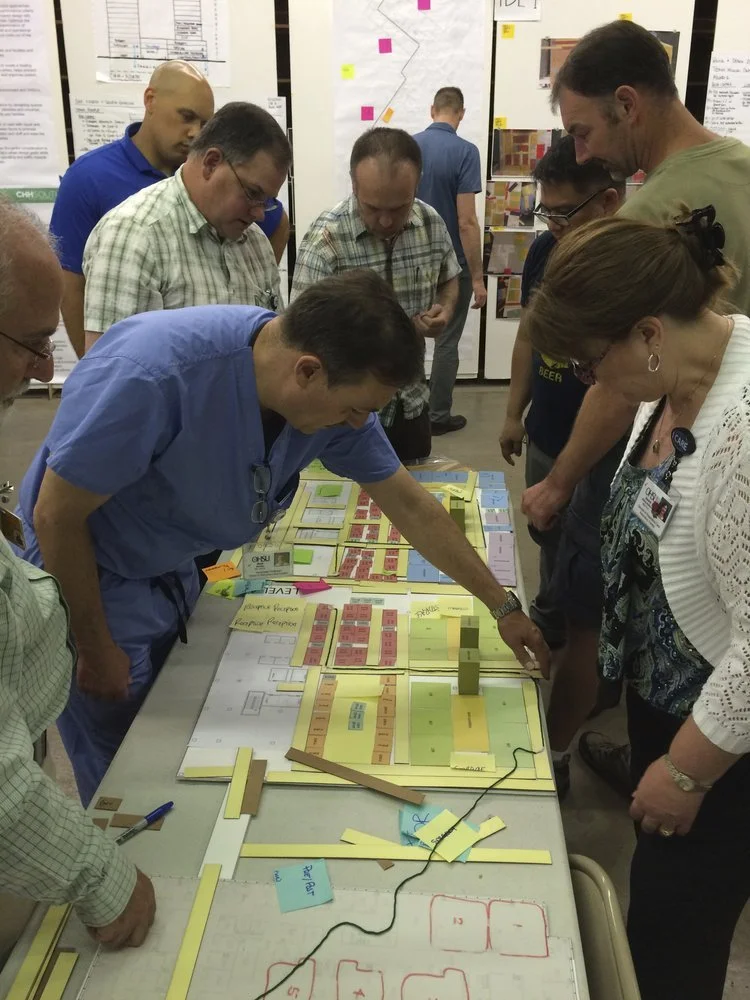

Nine multi-day workshops—involving hundreds of stakeholders—were used to fine-tuned operations and layout needs for each department.

The Results

Since opening, CHH-South has housed six hundred patients daily with improved care integration, providing state-of-the-art ambulatory care in a setting designed to adapt gracefully to stressors—a point proven out during the pandemic response.

Promising Outcomes

The design has streamlined care through co-location, physically shortening referral loops and enhancing collaboration among specialists

Flexible clinic re-sizing through shifting non-load-bearing partitions has allowed minor adjustments to suit departmental needs.

Minor renovations and reassignments of space have already been carried out with minimal disruption.

The ability to rearrange proved crucial during the pandemic converting areas for COVID-safe, isolated care with minimal modifications.

New services can be built out and plugged into the existing infrastructure relatively quickly due to the deliberate surplus room.

General confidence in the framework for accommodating upgrades or overhauls while avoiding gut renovations.

CHH-South demonstrates that investing in flexibility and foresight can pay dividends in a healthcare building’s performance and longevity, ensuring it remains flexible enough to expect the unexpected.

-

Architects

Zimmer Gunsul Frasca Architects, LLP (ZGF)

Client

Oregon Health & Science University, Portland Oregon, USA (OHSU)

Building area

39,292 m2 (401,412 sq. ft.)

Primary System

Structural system (steel) grid varies due to existing below grade parking structure. Maximum bay size is 42’-9” x 28’-0” (13.03m x 8.53m) and smallest (at corners) is 20’-5” x 16’-6” (6.22m x 5.03m). To improve grid spacing, there are some transfers of columns to the parking levels via angled columns. Lateral seismic system is a moment frame. Two stair cores are off center and grouped with elevators (split between public and patient/staff), main mechanical/heating ventilation air condition, HVAC, shafts, stacked electrical and technology rooms. Smaller plumbing risers are adjacent to structural columns.

Floor to floor heights: Generally, 15’-0”/4.57m, increased at podium levels (16’/4.88m), first floor (20’-10”/6.35m) and the interstitial mechanical level (24’/7.32m)

Location of primary mechanical and electrical systems, those typically found in a Central Plant, are described later under “System Organization.”

Secondary System

Non-loadbearing interior walls and mechanical electrical plumbing, MEP, distribution

Tertiary System

Medical equipment (movable and fixed), office equipment, computer technology, furnishings and art.

Sustainability

The project was certified as LEED Gold® by the U.S. Green Building Council.

Start of design 2014

Groundbreaking 2016

Opening 2019