Molenvliet

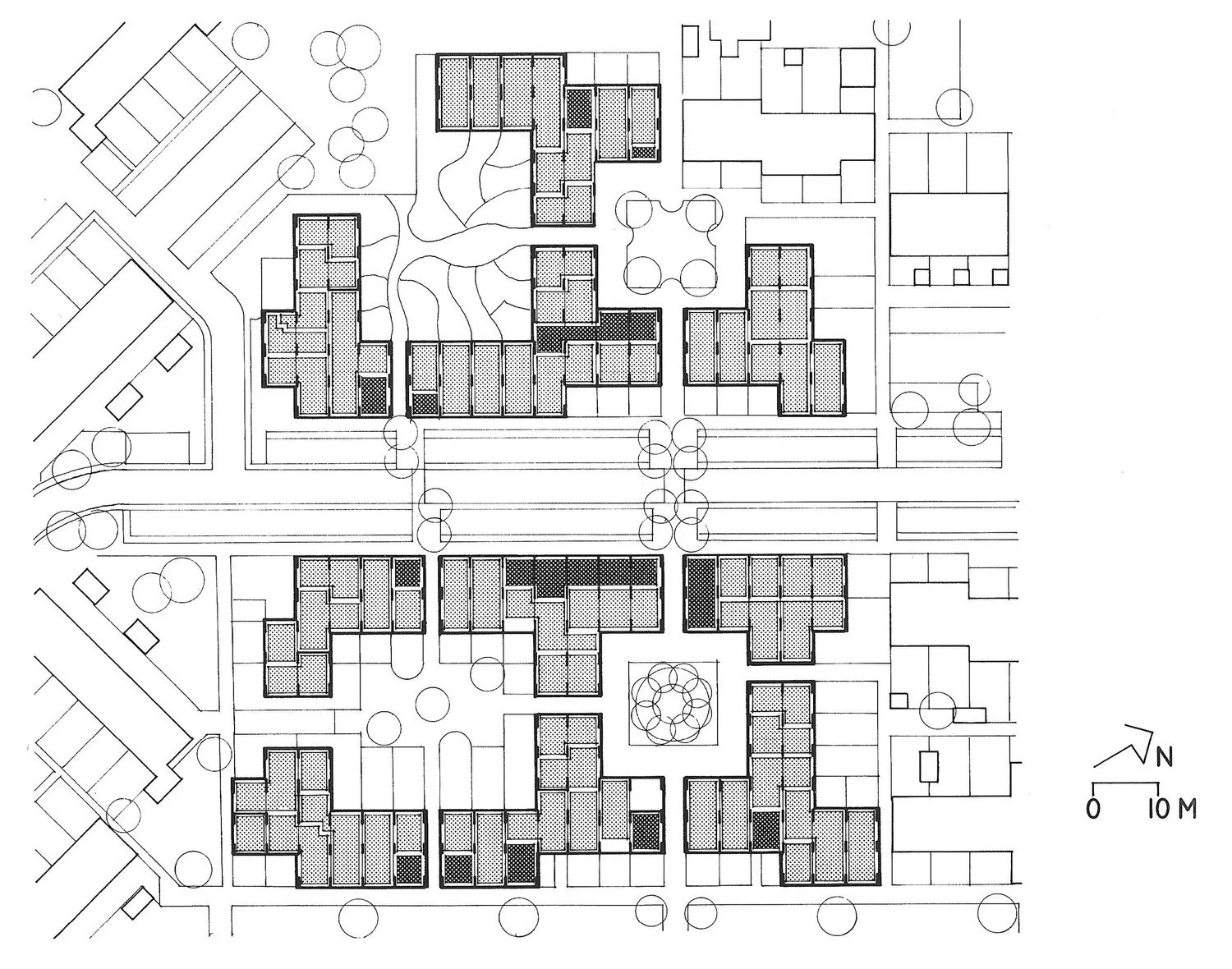

Molenvliet is one of the world’s first full-scale implementations of Open Building—a rental housing complex composed of 120+ units structured in a traditionally Dutch vernacular, each filled-in with a uniquely tailored layout and facade

Molenvliet (1977)

Papendrecht, Netherlands

Frans van der Werf, KOKON Architects

The Challenge

After winning a design competition for building new housing, Frans van der Werf of Werkgroep KOKON Architects set out to design a support structure to accommodate 120+ units that would ensure long-term adaptability and give residents real design agency, all without compromising cost, timeline, a Dutch architectural themes, or urban harmony.

Key Issues

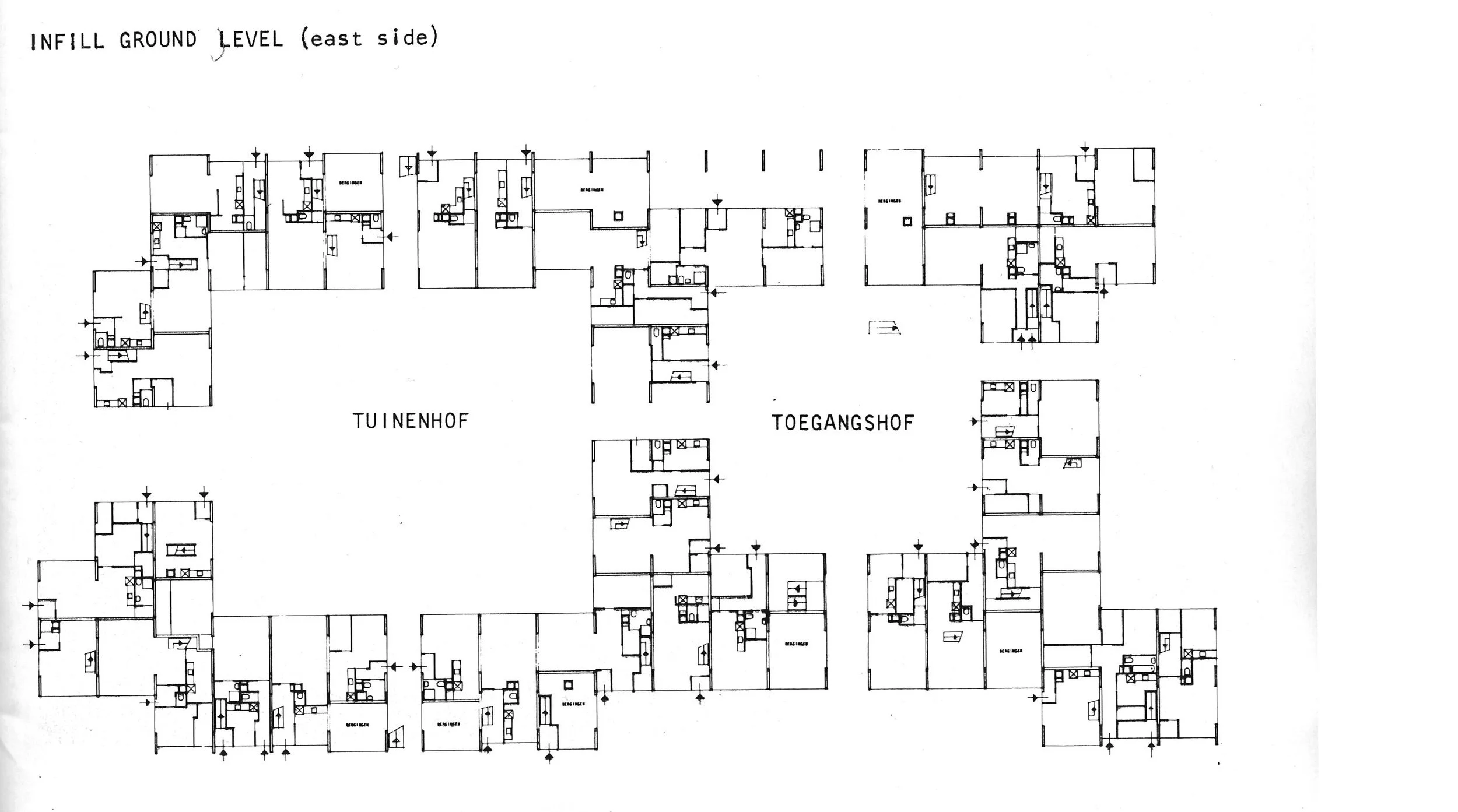

Each household would have unprecedented involvement in designing their own apartment’s layout and infill.

A replicable structural system had to support highly varied unit types and internal programs.

Customization had to be affordable within social housing cost constraints.

Interiors needed to be reconfigurable across decades of occupancy and changing tenants.

The neighborhood needed to feel like a coherent whole and fit with its cultural surroundings.

The Ambitions

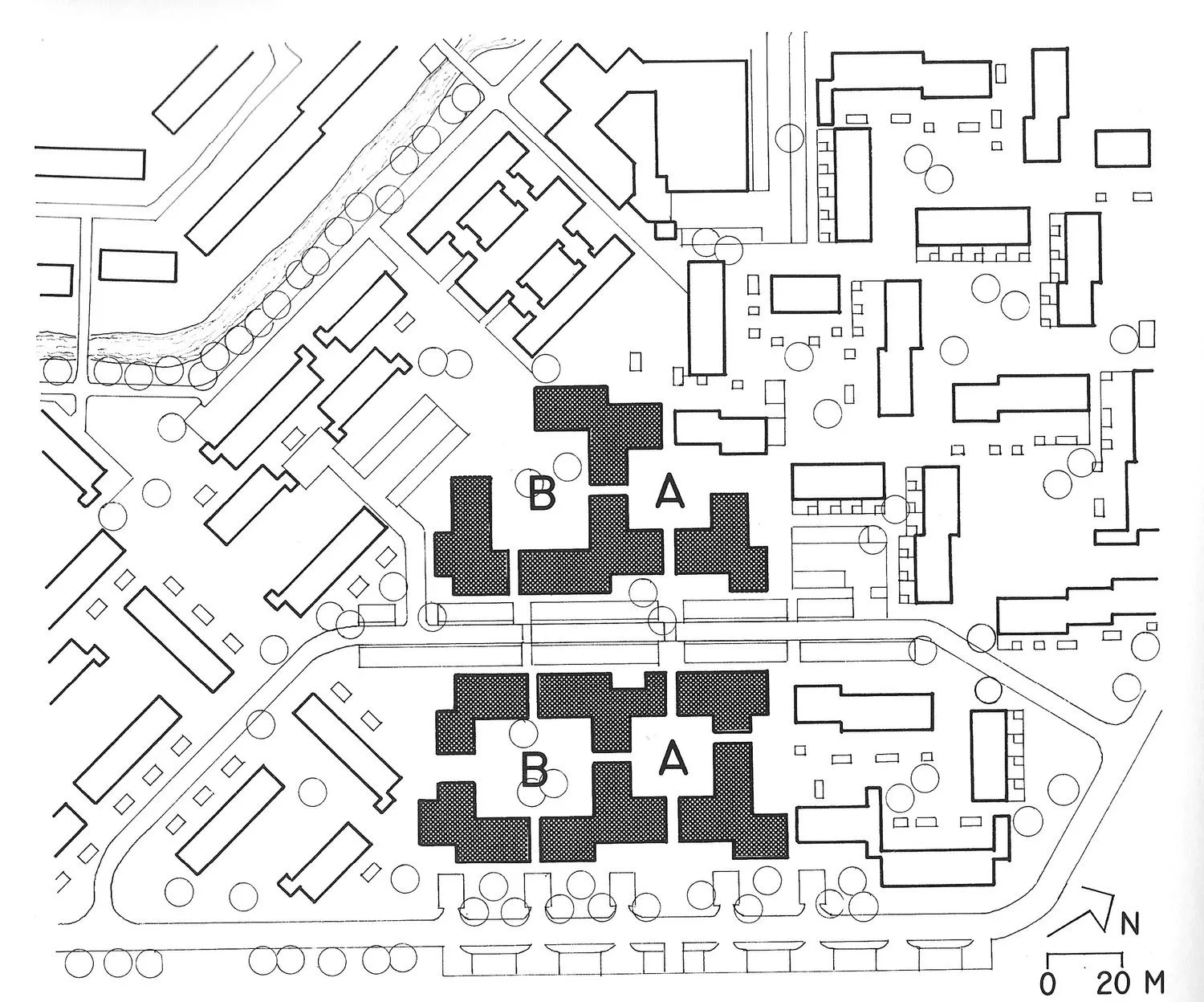

A participatory design process wherein residents would customize their own spaces—made possible by separating the support structure from the modifiable interior layouts (infill) and facades.

Strategic Goals

A durable support structure for efficient, repeatable construction and long-term stability.

Customizable infill for each dwelling so residents could choose layouts tailored to their needs.

A modular facade system that would allow user to choose the way their resident presented itself publicly.

Organizing units around shared gardens and courtyards to reinforce communal life and create a safer neighborhood.

The Realization

Completed as planned in 1977, Molenvliet delivered 123 unique dwellings using a clear separation of base structure and user-driven infill. Each apartment was built from resident-approved drawings and expressed its own identity on the facade.

Vital Design Choices

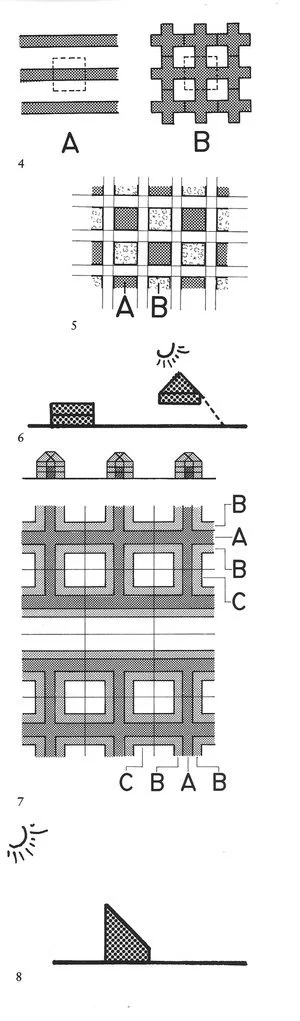

The reusable tunnel-forms enabled construction of the load-bearing walls and slabs to be built with reusable forms speed and regularity.

A kit-of-parts using a timber frame element gave shape to the range of facade choices, including colors and the placement of windows and doors.

Regular placement of openings cast into slabs enabled vertical installation service shafts and stairs.

Interiors could be easily remodeled or replaced without impacting the support structure.

The Results

Molenvliet became an international benchmark for Open Building housing. The buildings’ support structure required little change after 30+ years, while infill and facades have easily adapted to match evolving needs.

Promising Outcomes

Residents enjoyed personalizing their units, encouraging strong tenant buy-in and long-term satisfaction.

Renovations occurred without structural changes, and over the ensuing decades, the buildings’ support structures have remained intact.

The dwellings maintained a prototypically Dutch architectural coherence with modular facades that also conformed to traditional Dutch streetscape logic.

The model for designing a replicable framework has influenced follow-up housing projects across the Netherlands.

Molenvliet proves that with careful planning, social housing can combine individuality, adaptability, and architectural coherence. Its enduring value affirms that the dynamic of sound structural support with flexible infill systems empowers both residents and long-term sustainability.

-

Architect

Frans van der Werf, KOKON Architects

Construction Timeline

Support: 1976; Infill: 1977 (renovations at intervals since that time)

Owner

Housing Association ‘Papendrecht’

Dwellings

120+ rental dwellings; 4 office spaces

Support construction

Roos Bouw, Rotterdam: Concrete tunnel-formed concrete cast in place, with openings in slabs for shared vertical mechanical systems and internal stairs; kit-of-parts facade

Infill provision

Nijhuis Infill System, Rijssen, completed by conventional Dutch interior construction